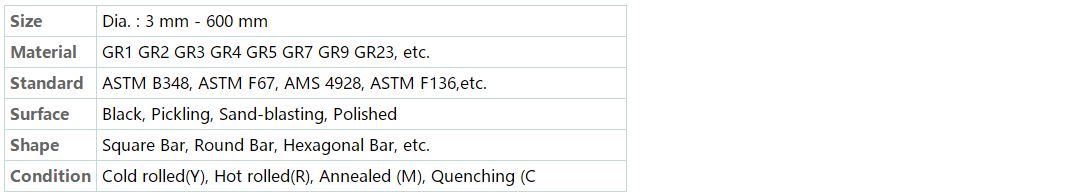

Top Titanium stocks a wide range of titanium rod, including a complete line of commercially pure and medical titanium rod. Titanium connecting rod, titanium rod in femur, titanium welding rod, titanium filler rod, titanium threaded rod, Nitinol rod etc, can all be met. It can be supplied in random lengths or cut into fixed lengths, according to your precise dimensions.

Titanium is highly resistant to chloride-containing media, practically all salt solutions, seawater, a range of acids, organic and inorganic chemicals and gases. The high environmental resistance is primarily based on a very thin, tenacious and highly protective surface oxide film. The oxide film provides high resistance to erosion in high velocity process streams. It is non-magnetic and characterized by a high melting point, high strength-to-weight ratio and a low modulus of elasticity.

Application:

Chemical processing, Medical instruments, Aerospace, Industry, Navigation, Smelting, Chemical plants, Machinery and equipment, Electroplating equipment, Precision instruments standard parts, Titanium wind leaf in power used, etc.

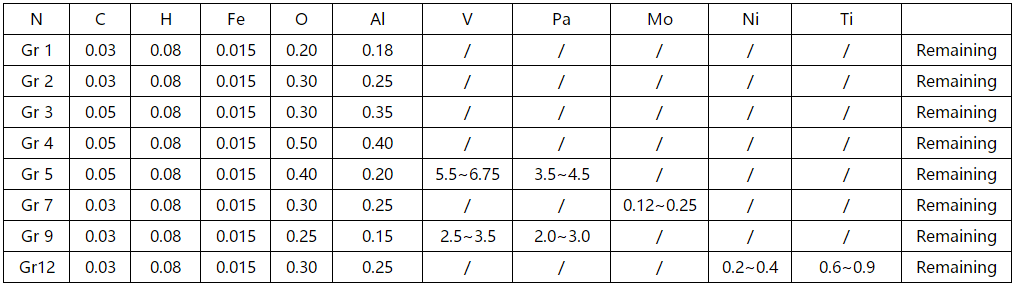

Chemical requirements (Nominal %)

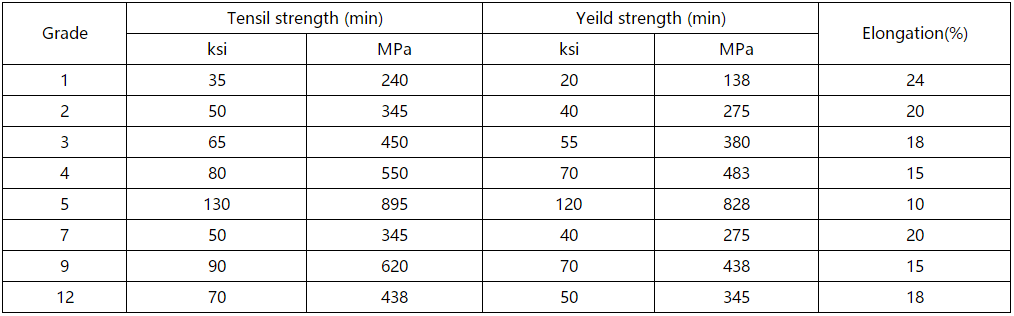

Mechanical requirements

Features :

Low density and high strength;

Excellent corrosion resistance;

Good resistance to effect of heat;

Excellent bearing to cryogenic property;

Non Magnetic and non-toxic;

Good thermal properties.

Testing:

Corrosion test

Eddy Current test

Mechanical test

Microstructure test

Titanium rod is produced and certified to Medical (ASTM F67, ASTM F136, ISO5832-2, ISO5832-3), Aerospace (AMS 4928, AMS 2631b), Industrial (ASTM B348) standards. Stock production is aligned to ASTM, AMS and ISO standards with other standards available on made to order.